ENGINEERING SERVICES AND CONSULTING Srl

Additive manufacturing machines: 3D printers SLA technology with LASER light source and LED with a DLP®.

The 3D printers developed by ESC are

based on stereolithographic technology (SLA) and use a light

source in the UV field to produce objects by curing

photosensitive resins.

The principle is the one of additive manufacturing, where a

virtual 3D model of the object to be built is sliced into layers

of defined thickness, generating several 2D profiles that will

then be printed in sequence on top of each other to generate the

physical object.

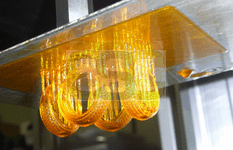

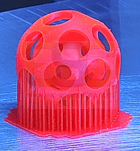

DLP 75-50

The SLA DLP 75-50 printer uses a LED light source and through a

DLP® projector designs 2D images, obtained by slicing the 3D

model, on the bottom of a vat containing resin solidifying it in

illuminated areas. A platform, moved by a precision axis, rises

above the liquid resin every time a layer is completed. In the

end, the platform moves away from the liquid resin allowing the

finished object to be discharged.

The DLP 75-50 printer, using Texas Instrument's DLP® system, is

able to solidify the entire resin layer at each exposure (a few

seconds of duration) allowing a high printing speed and is able

to produce small parts with high resolution.

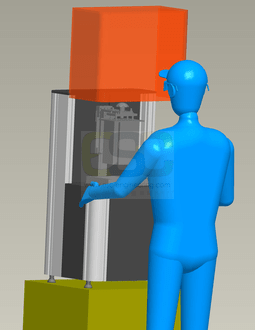

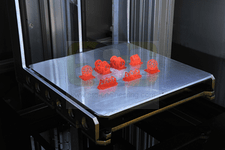

380B LASER

The SLA 380B LASER printer uses a laser source whose beam,

through an optical system composed of a galvanometer scanner

head and a field lens, draws the 2D profiles obtained by slicing

the 3D model on the free surface of the resin. A platform, moved

by a precision axis, supports the various layers printed by

lowering in the liquid resin every time a layer is completed. In

the end, the platform resurfaces from the liquid resin allowing

the finished object to be discharged.

The 380B LASER printer uses a laser system to produce large

parts with medium-high resolution.

The machine complies with the applicable European standards.

Download the brochure380

B LASER e DLP 75-50

Contact

us we will be glad to provide you with all the information

you need.

Copyright 2007-2017 - ESC Engineering Services and

Consulting Srl - P. IVA 09705560010

Privacy Policy