ENGINEERING SERVICES AND CONSULTING Srl

Additive manufacturing: Start-up of a 3D

printing workshop.

After designing our 3D printer models

for SLA additive manufacturing we realized the first two models,

one with LED + DLP® light source and one with laser source. These

first two units were made for a Chinese company and shipped to

their Shenzhen facility.

After designing our 3D printer models

for SLA additive manufacturing we realized the first two models,

one with LED + DLP® light source and one with laser source. These

first two units were made for a Chinese company and shipped to

their Shenzhen facility.

After the two printers

arrived in China, we installed them in the company's facilities,

carrying out functional testing and starting the training of local

engineers and technicians who operate the workshop.

After the two printers

arrived in China, we installed them in the company's facilities,

carrying out functional testing and starting the training of local

engineers and technicians who operate the workshop.

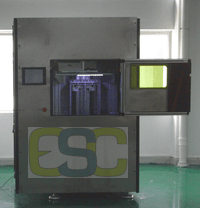

The printers installed.

Two machines for additive manufacturing

with stereolithographic (SLA) technology have been installed.

The first one uses an LED light source and through a

DLP® projector designs 2D images, obtained by slicing the 3D

model, onto the bottom of a vat containing resin and solidifies it

in illuminated areas. Using Texas Instrument's DLP® system, the

printer is able to solidify at each exposure (a few seconds of

duration) the entire resin layer allowing a high printing speed

and is able to produce small parts with high resolution.

The first one uses an LED light source and through a

DLP® projector designs 2D images, obtained by slicing the 3D

model, onto the bottom of a vat containing resin and solidifies it

in illuminated areas. Using Texas Instrument's DLP® system, the

printer is able to solidify at each exposure (a few seconds of

duration) the entire resin layer allowing a high printing speed

and is able to produce small parts with high resolution.

The second one uses a

laser source whose beam, through an optical system composed of a

galvanometer scanner head and a field lens, draws the 2D profiles

obtained by slicing the 3D model on the resin free surface.

The second one uses a

laser source whose beam, through an optical system composed of a

galvanometer scanner head and a field lens, draws the 2D profiles

obtained by slicing the 3D model on the resin free surface.

The use of the laser allows to produce large parts with

medium-high resolution.

More information about our 3D printers can be found here.

Contact us we will be glad to provide you with all the information you need.

Copyright 2007-2017 - ESC Engineering Services and

Consulting Srl - P. IVA 09705560010

Privacy Policy