ENGINEERING SERVICES AND CONSULTING Srl

Additive technologies: family of 3D SLA

printers.

In our daily work as mechanical engineers we have been

using additive manufacturing for 20 years, during which we have

had the opportunity to test nearly all technologies and experience

their technological evolution: at the beginning we talked about

fast prototyping then, passing through less popular definitions,

we got to talk about 3D printing (mass diffusion) and then about

additive manufacturing (manufacture in volumes).

In our daily work as mechanical engineers we have been

using additive manufacturing for 20 years, during which we have

had the opportunity to test nearly all technologies and experience

their technological evolution: at the beginning we talked about

fast prototyping then, passing through less popular definitions,

we got to talk about 3D printing (mass diffusion) and then about

additive manufacturing (manufacture in volumes).

With this background and

knowledge combined with our complementary technological skills and

expertise (mechatronics, process control) and with the help of

highly qualified partners where our knowledge was not high enough,

we decided to enter this world. In 2012, we started to analyze the

market and conduct some preliminary projects and then start

designing a family of printers with SLA (stereolithographic)

technology at the beginning of 2014.

With this background and

knowledge combined with our complementary technological skills and

expertise (mechatronics, process control) and with the help of

highly qualified partners where our knowledge was not high enough,

we decided to enter this world. In 2012, we started to analyze the

market and conduct some preliminary projects and then start

designing a family of printers with SLA (stereolithographic)

technology at the beginning of 2014.

Why stereolithographic technology? First of all we decided to work

with plastics and then we excluded the molten wire technology

(FDM®/FFF) considering the high number of competitors that was

entering the market. We dropped sintering and polymer jet

technologies because we thought the development time would have

been too long for us and, in the end, the most suitable technology

came out to be SLA.

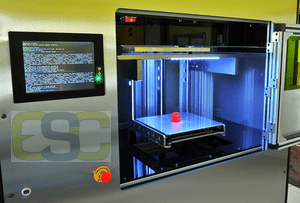

LED light source + DLP®.

This SLA version of the

printer uses a LED light source and through a DLP® projector

designs 2D images, obtained by slicing the 3D model, on the bottom

of a vat containing resin solidifying it in illuminated areas. A

platform, moved by a precision axis, rises above the liquid resin

every time a layer is completed. In the end, the platform moves

away from the liquid resin allowing the finished object to be

discharged.

This SLA version of the

printer uses a LED light source and through a DLP® projector

designs 2D images, obtained by slicing the 3D model, on the bottom

of a vat containing resin solidifying it in illuminated areas. A

platform, moved by a precision axis, rises above the liquid resin

every time a layer is completed. In the end, the platform moves

away from the liquid resin allowing the finished object to be

discharged.

Using Texas Instrument's DLP® system, the printer is able to

solidify at each exposure (a few seconds of duration) the entire

resin layer allowing a high printing speed and is able to produce

small parts with high resolution.

Learn more about our 3D SLA DLP® printers on this page.

Laser light source.

This version uses a laser source whose

beam, through an optical system composed of a galvanometer scanner

head and a field lens, draws the 2D profiles obtained by slicing

the 3D model on the resin free surface. A platform, moved by a

precision axis, supports the various layers printed by lowering in

the liquid resin every time a layer is completed. In the end, the

platform resurfaces from the liquid resin allowing the finished

object to be discharged.

This version uses a laser source whose

beam, through an optical system composed of a galvanometer scanner

head and a field lens, draws the 2D profiles obtained by slicing

the 3D model on the resin free surface. A platform, moved by a

precision axis, supports the various layers printed by lowering in

the liquid resin every time a layer is completed. In the end, the

platform resurfaces from the liquid resin allowing the finished

object to be discharged.

The use of the laser allows to produce large parts with

medium-high resolution.

Learn more about our 3D SLA Laser printers on this page.

Contact us we will be glad to provide you with all the information you need.

Copyright 2007-2017 - ESC Engineering Services and

Consulting Srl - P. IVA 09705560010

Privacy Policy