ENGINEERING SERVICES AND CONSULTING Srl

Special automatic machines: dot matrix impact printheads manufacturing.

Once the printhead was designed, we were involved in the design and construction of the special machines needed for mass production.

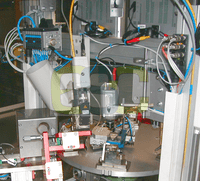

Automatic selection machine.

Among the components that

are part of the printhead (about 35 different codes) the one with

the highest technology is the armature (in our case 24 per head):

it is made of cobalt steel and after being punched and coined

(with a die made by our partner) it must be 100% tested. In order

to do this, we have developed a special automatic machine that

verifies different parameters (thickness, flatness,...) and

selects the good armatures from the waste ones.

Among the components that

are part of the printhead (about 35 different codes) the one with

the highest technology is the armature (in our case 24 per head):

it is made of cobalt steel and after being punched and coined

(with a die made by our partner) it must be 100% tested. In order

to do this, we have developed a special automatic machine that

verifies different parameters (thickness, flatness,...) and

selects the good armatures from the waste ones.

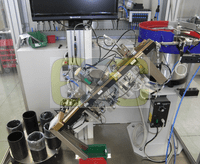

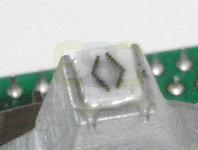

Laser brazing machine.

The armatures must then be

joined to the needles (diameter 0.2-0.25 mm) by brazing. This

operation is carried out by a special automatic machine: a laser

brazing machine which, after having positioned the needle

and armature in a precise position, deposits the brazing paste

which is then melted using a laser beam.

The armatures must then be

joined to the needles (diameter 0.2-0.25 mm) by brazing. This

operation is carried out by a special automatic machine: a laser

brazing machine which, after having positioned the needle

and armature in a precise position, deposits the brazing paste

which is then melted using a laser beam.

This is a critical operation that is constantly monitored by means

of two cameras.

Once this group has been completed, the

entire printhead is assembled using a series of standard

machines (tangential grinding, washing machines, ovens, etc.)

until the complete head is obtained.

Special grinding machine.

Once the assembly has been

completed, the needles protruding from the printhead guide should

be ground to ensure their flatness and height of protrusion.

Once the assembly has been

completed, the needles protruding from the printhead guide should

be ground to ensure their flatness and height of protrusion.

For this operation, a special grinding machine is used that

flattens the needles at a predefined height and carries out a

brushing operation to eliminate dust and grinding waste from the

end of the needles.

Parametric test equipment.

After the needle grinding

operation the printhead can be considered as finished, it is now

necessary to measure the key parameters (needle stroke, impact

force, coil resistance, etc.) to check that they correspond to the

design parameters.

After the needle grinding

operation the printhead can be considered as finished, it is now

necessary to measure the key parameters (needle stroke, impact

force, coil resistance, etc.) to check that they correspond to the

design parameters.

For this operation we have designed and built a parametric

test equipment that measures, collects and stores the values

of these key parameters in a database.

Only after the printhead has passed this test can it start the

preliminary running-in step and then be installed on the printer.

Shipment.

The machines described

above (some in 2 units) were shipped to China where they were

installed in a specific workshop for the production of

the heads we designed.

The machines described

above (some in 2 units) were shipped to China where they were

installed in a specific workshop for the production of

the heads we designed.

Interested at our design activities? Interested at our special automatic machines? Contact us we will be glad to provide you with all the information you need.

Copyright 2007-2017 - ESC Engineering Services and

Consulting Srl - P. IVA 09705560010

Privacy Policy